You’ve probably heard that undercarriage typically accounts for 20 percent of the purchase price of a track machine. But did you also know that it accounts for 75 percent or more of the machine’s lifetime repair tab?

Because it both supports and propels track-type machines, the undercarriage is subjected continuously to the relentless forces of wear and tear, day in and day out. Everything, from the conditions of the work environment to the way a machine is operated and the surface on which it is driven, affects the longevity and performance of these components.

Performing routine maintenance and timely service on undercarriage helps not only to maximize a machine’s power, stability, and safety, but also to minimize operating costs over the course of its life.

Ring Power is fortunate to have four, full service undercarriage (U/C) shops ― in St. Augustine, Tampa, Orlando and Ocala ― equipped and staffed to keep up with customer demand and strategically located to serve customers throughout North and Central Florida. All promise 12-hour turnaround and are prepared to do whatever it takes to deliver on that promise.

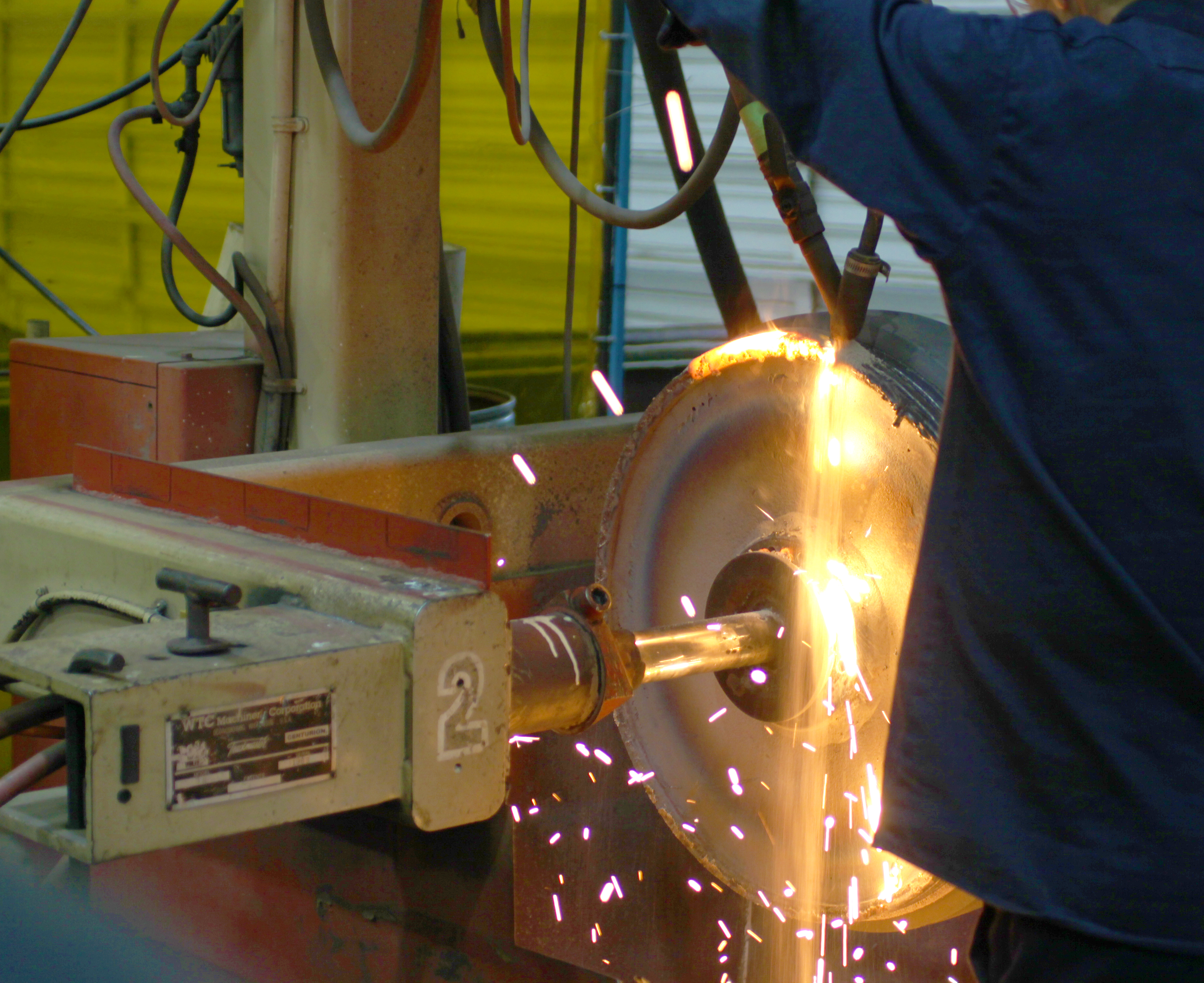

Undercarriage work is physically demanding, requiring a level of cooperation and teamwork unmatched by our other service departments. Whether a machine needs new pins and bushings installed or old ones turned; idlers and rollers replaced or reconditioned; track shoes replaced or rail repaired ― it all starts on the wash rack. There, compacted dirt must first be dislodged (sometimes with air-powered needle chippers!) and washed away so that the track groups can be removed and taken to the track press. Once exposed, the individual components can also be removed and either reconditioned or replaced, before the reassembly process begins.

So, how do our U/C shops manage to turn every undercarriage job around, day after day, in 12 hours? U/C shop foremen, Matt Harden (Tampa), Daryl Gandy (WCC), Brian Phelps (Orlando) and Jody Peavy (Ocala) agree. “Communication is the key,” they maintain.

Internally, each foreman meets at least once a month (and, depending on the workload, as often as once a week) with his branch service manager and holds toolbox meetings twice a month with his techs and service advisors to discuss best practices, review procedures and recommend ways to improve safety.

Our product support sales reps also play a huge role. By continuously monitoring the condition of the undercarriage on their customers’ track machines, they know when service will be needed and can even prepare work orders in advance. This allows the foremen to pre-order the necessary parts so that work can begin as soon as the machine arrives.